Your location:Home > Products

> Medical PCB

Your location:Home > Products

> Medical PCB

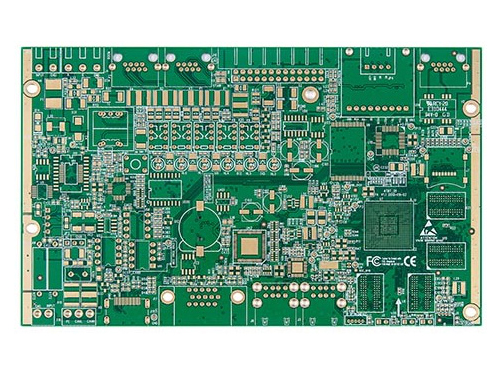

Number of pcb layers of medical equipment: 6L

Plate thickness: 1.6mm

Outer copper thickness: 1 OZ

Inner copper thickness: 1 OZ

Minimum hole diameter: 0.2mm

Minimum line width/line spacing: 3mil

Surface treatment: gold deposit

Product application: X-ray detector

Process difficulty: 8mil BGA

As diagnostic, monitoring and therapeutic equipment, electronic products have made great contributions to the health care industry. With the development of electronic technology, the medical application of these electronic devices becomes more and more important.

Development and sustainable development become more efficient and intensive, bringing infinite new possibilities.

The core of these medical devices is the printed circuit board. PCBs in the medical industry are highly specialized to meet the unique limitations of medical equipment. In many medical applications, small packages are needed to meet the size requirements of implants or emergency room monitors. Therefore, medical printed circuit board is usually a special high-density interconnection circuit board, also known as high-density printed circuit board. The medical printed circuit board can also be made of flexible substrate, allowing the printed circuit board to bend during use, which is important for both internal and external medical devices.

Due to its associated health effects, the standards for medical PCBs are higher than for most other types of PCBs. In addition to meeting strict medical requirements and regulations, refolding and reliability are two basic elements that medical PCB suppliers must achieve.

Contact: Mr. Zheng

Contact: Mr. Zheng Mobile phone: 13544145687

Mobile phone: 13544145687 Tel.: 0755-23504156

Tel.: 0755-23504156 Email: gypcb68@163.com

Email: gypcb68@163.com Website: www.gydcpcb.com

Website: www.gydcpcb.com Address of Shenzhen Marketing Department: B212, Yinong Building, No. 4, Haoye Road, Qiaotou Community, Fuhai Street, Bao'an District, Shenzhen

Address of Shenzhen Marketing Department: B212, Yinong Building, No. 4, Haoye Road, Qiaotou Community, Fuhai Street, Bao'an District, Shenzhen Address of Chengdu Marketing Department: 14/F, Building B, Zijingnian, No. 5, Chuangye Road, High tech Zone, Chengdu, Sichuan

Address of Chengdu Marketing Department: 14/F, Building B, Zijingnian, No. 5, Chuangye Road, High tech Zone, Chengdu, Sichuan Factory address: Building 4, Wansha Industrial Park, Gonghe Village, Shajing Street, Bao'an District, Shenzhen

Factory address: Building 4, Wansha Industrial Park, Gonghe Village, Shajing Street, Bao'an District, Shenzhen