Your location:Home > Products

> Route board proofing

Your location:Home > Products

> Route board proofing

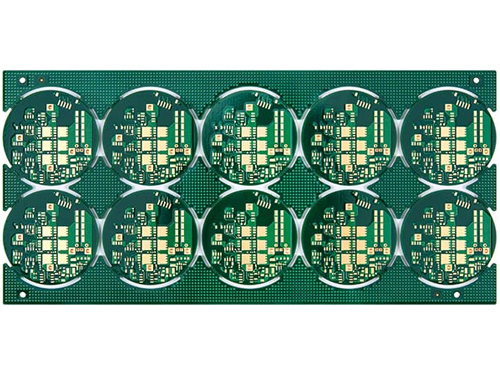

PCB proofing: 8L

Plate thickness: 2.0mm

Outer copper thickness: 3oz

Inner copper thickness: 2oz

Minimum hole diameter: 0.25mm

Minimum line width/line spacing: 5mil

Surface treatment: gold deposit

Product use: server power panel

Process difficulty: 3oz copper thickness 3rd order blind buried hole

PCB proofing As the carrier of electronic components, the size and performance of the circuit board are determined by the number of layers of the multilayer board and the precision design degree of the circuit. This industrial robot adopts an 8-layer board design, with 3 mi l/3 mi l line width and line matching. At the same time, it encapsulates 10 groups of ICs and 12 groups of BGAs, which can be called a high-end product of high-precision printed circuit boards.

Main Process Characteristics of PCB Proofing Embedded Blind Orifice

1. Design of buried blind hole;

2. 3mil line width and line spacing;

3. BGA spherical design shall be uniform in size;

4. IC green oil bridge 4mil/4mil.

Contact: Mr. Zheng

Contact: Mr. Zheng Mobile phone: 13544145687

Mobile phone: 13544145687 Tel.: 0755-23504156

Tel.: 0755-23504156 Email: gypcb68@163.com

Email: gypcb68@163.com Website: www.gydcpcb.com

Website: www.gydcpcb.com Address of Shenzhen Marketing Department: B212, Yinong Building, No. 4, Haoye Road, Qiaotou Community, Fuhai Street, Bao'an District, Shenzhen

Address of Shenzhen Marketing Department: B212, Yinong Building, No. 4, Haoye Road, Qiaotou Community, Fuhai Street, Bao'an District, Shenzhen Address of Chengdu Marketing Department: 14/F, Building B, Zijingnian, No. 5, Chuangye Road, High tech Zone, Chengdu, Sichuan

Address of Chengdu Marketing Department: 14/F, Building B, Zijingnian, No. 5, Chuangye Road, High tech Zone, Chengdu, Sichuan Factory address: Building 4, Wansha Industrial Park, Gonghe Village, Shajing Street, Bao'an District, Shenzhen

Factory address: Building 4, Wansha Industrial Park, Gonghe Village, Shajing Street, Bao'an District, Shenzhen