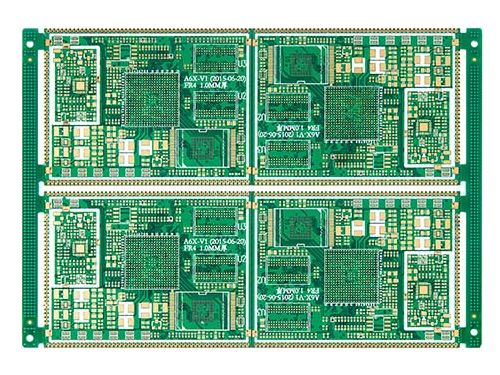

Number of layers: 8L

Plate thickness: 1.6mm

Outer copper thickness: H OZ

Inner copper thickness: H OZ

Minimum hole diameter: 0.15 mm

Minimum line width/line spacing: 4mil

Surface treatment: gold deposit

Product use: car audio and video

Process difficulties: 10:1 aspect ratio

Automotive pcb half orifice combines mechanical and electronic equipment. Modern automobile technology combines traditional technology with advanced science and technology, such as manual interior decoration and GPS propulsion. In modern cars, electronic devices with different functions at different locations come from different types of PCBs.

According to the substrate materials, automotive PCB can be divided into two categories: inorganic ceramic based PCB and organic resin based PCB. Ceramic PCB has high temperature resistance and excellent dimensional stability, which can be directly applied to high-temperature motor systems. However, it has poor ceramic manufacturability and high cost. At present, with the development of resin based substrate materials in heat resistance, resin based PCB has been widely used in automobiles, and substrate materials with different properties are applied in different locations.

Contact: Mr. Zheng

Contact: Mr. Zheng Mobile phone: 13544145687

Mobile phone: 13544145687 Tel.: 0755-23504156

Tel.: 0755-23504156 Email: gypcb68@163.com

Email: gypcb68@163.com Website: www.gydcpcb.com

Website: www.gydcpcb.com Address of Shenzhen Marketing Department: B212, Yinong Building, No. 4, Haoye Road, Qiaotou Community, Fuhai Street, Bao'an District, Shenzhen

Address of Shenzhen Marketing Department: B212, Yinong Building, No. 4, Haoye Road, Qiaotou Community, Fuhai Street, Bao'an District, Shenzhen Address of Chengdu Marketing Department: 14/F, Building B, Zijingnian, No. 5, Chuangye Road, High tech Zone, Chengdu, Sichuan

Address of Chengdu Marketing Department: 14/F, Building B, Zijingnian, No. 5, Chuangye Road, High tech Zone, Chengdu, Sichuan Factory address: Building 4, Wansha Industrial Park, Gonghe Village, Shajing Street, Bao'an District, Shenzhen

Factory address: Building 4, Wansha Industrial Park, Gonghe Village, Shajing Street, Bao'an District, Shenzhen